| November

2000 |

|

|

|

Dragonair/CNAC Building

Classical symmetry

Hong

Kong is full of glass boxes -- those reflective uniforms in silver,

blue or black that dot the skyline on both sides of the harbour.

Adoption of a modernist idiom, however, need not translate into

anonymity and blandness. Hong

Kong is full of glass boxes -- those reflective uniforms in silver,

blue or black that dot the skyline on both sides of the harbour.

Adoption of a modernist idiom, however, need not translate into

anonymity and blandness.

At Chek Lap Kok international

airport there is a model of classical symmetry which is modernist

in expression but by no means pedestrian.

The

six-storey high Dragonair/CNAC Building, developed at a total project

cost of HK$1.4 billion, consists of two identical but separate blocks

linked together by a four-storey high atrium. An external colonnade

of stainless steel-clad columns provides a vertical counterpoint

to the horizontality of the overall design, responding to the call

for form to follow function with an easy poise.

The building's

location, on a 1,440 sq m site overlooking Tung Chung Bay

in the eastern corner of the airport island, immediately posed three

challenges for the architect: height restriction; aircraft noise;

and a corrosive seaside environment.

The solution

to these challenges, as developed by architect Wong Tung & Partners

Ltd (WTPL), is a simple yet elegant one.

The need

to comply with height restrictions imposed by the glide path generated

a low building which is rectangular in plan and modernist in expression

but with classically derived proportions. The two wings on either

side of the atrium form pavilions defined by the projecting roof

element while the Flight Training Centre to the east of the office

pavilions terminates and defines the forecourt space.

The road

system, according to WTPL architect Edward Billson, forms a perfect

hippodrome of Roman proportions.

The common

atrium gives access to the main lift lobbies which by necessity

are located at the end of the rectangular footprint, thus creating

large, open office floors which provide maximum flexibility in terms

of layout.

The problem

of aircraft noise was addressed by the adoption of a double-skin

cavity wall system which provides 60 dBa of sound attenuation. A

800 mm cavity separates the 19 mm thick external layer of fully-tempered

glass and the inner layer, which is an insulated low E coated unit.

According

to Mr Billson, acoustic engineers required three layers of glass

with a minimum of 200 mm between two of the layers. The cavity wall

system not only answers the engineers' requirements, but also avoids

condensation problems through its use of acoustic baffles to ventilate

the system. The cavity also facilitates maintenance and improves

the building's thermal performance.

Although

studies in the US have indicated that natural light enhances productivity,

clear glass is rarely used in Hong Kong both because of concern

for the visibility of internal chaos, especially in strata-title

buildings; and concern for the view out of the building, which is

not always a pleasant one in urban Hong Kong.

The Dragonair/CNAC

Building, however, proves ideal for its application because of the

spectacular views of Tung Chung Bay and the peaks of Lantau as well

as the fact that it is an end-user building in which the interior

layout can be coordinated. The low E glass used increases light

transmission to 50 per cent, compared with 15 per cent for reflective

glass while maintaining the same shading coefficient. The interior

was carefully planned to ensure that workstations sit away from

the glass line.

"We

believe the benefits of a large view and natural lighting outweigh

concerns for not being able to put storage against the external

wall," said David J Clarke, deputy director of WTPL.There are

other advantages to the choice of cladding material - glass is also

the best material for resisting the corrosive effects of a seafront

environment, and the clear glass fits the airport's low

reflectivity requirement for all structures.

Several

devices were employed by the architect to achieve the desired sense

of lightness for the building.

The

choice of clear glass is complemented by the method for fixing the

curtain wall, which is hung from Level 5 rather than supported on

every floor. By thus separating the building volume from its skin,

both the sense of volume and transparency are enhanced.

Much thought

was also given to the form of the brushed stainless steel pilotis

and the roof. The slender, 25 m high pilotis were designed with

entasis and therefore taper slightly from the middle to the top

and bottom. To create an illusion of lightness, they are lit at

the bottom, but not at the top. The large floodlights at the base

of the pilotis also throw light into the stainless steel soffit.

"The

idea of the lighting is to get the building to glow," Billson

explained. "The top of the pilotis is not lit because we wanted

the roof to float, seemingly unsupported, above the pilotis and

the building."

Mr Clarke

said the intention was to make the roof look almost as thin as a

folded card. To achieve that sense of lightness, every effort was

made to keep the roof free of electrical and mechanical installations.

Thus, lift machine rooms are provided in the basement while the

adjacent crew facility building is used to accommodate chillers

which are connected to the main building through pipelines running

through at the basement level.

Upswept

and projecting beyond the facade, the roof evokes images of Chinese

eaves for some but also invites the inevitable allusion to flight.

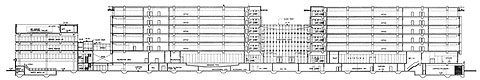

section A-A

"Our

intention was to look at things of quality at the airport and pick

up the vocabulary and materials without aping its imagery,"

Mr Clarke pointed out. "We deliberately avoided the aerofoil

cliche but at the same time the design called for a strong yet simple

roof expression." Light also suffuses the 20 m high, 24 m wide

and 26 m deep atrium through a louvred ceiling and mast-supported

skin walls. The 4.2 m by 1.5 m laminated glass panels are bolt-fixed

to a system of steel outriggers which are supported in turn by the

prestressed mast structures at 4.5 m centres. Design of the mast,

which is reminiscent of the masts on sailboats, required a lot of

engineering input, but the result is a support system which employs

the most minimal amount of steel to support the maximum area of

glass. Mr Billson said it was an environmentally responsible solution

as it makes the most efficient use of non-renewable resources. Aesthetically

it also continues the vertical rhythm of the pilotis across the

atrium connecting the two buildings.

The atrium

is described as an interstitial space which allows the typical office

to "break out" through a series of balconies that look

down on it from different perspectives. A sense of airiness was

achieved through the use of glass and the innovative fixing system,

which are complemented by a light colour palette, creating an ice

cube where the sense of freedom associated with the outdoors can

be experienced in the air-conditioned comfort of the indoors.

The building

is set on a cleft travertine plinth sourced from Mariotti, a respected

stonemason in Italy. Extending into the public space beyond the

building, the plinth is part of the architect's careful orchestration

of the user's experience of the project. This plan envisages the

user approaching the building via the big, open space paved by the

rough hewn stone and move towards the medium space defined by the

pilotis. Finally the user reaches the intimate space established

by a ground floor which sits back underneath a 7 m first floor cantilever

that provides weather protection without spoiling the sleek facade.

In addition

to a quiet working environment, the view and natural lighting, Dragonair

and CNAC staff also benefit from recreational facilities which include

a fitness centre -- described as having one of the best views of

all fitness centres in Hong Kong -- a 25 m long swimming pool; a

sports hall for ball games and aerobics; a number of lounge areas;

a reading room and a cafeteria which seats 400.

The 32,500

sq m of total gross floor area includes a separate training block

which houses a safety training module for cabin crew; a flight simulator

unit for A320 aircraft (provision is made for one more simulator

at a later date); inflight services mock-up; and lecture and debriefing

rooms.

client Dragonair

& CNAC (Group)

architect Wong Tung & Partners Ltd

project management Ove Arup & Partners and CITIC Project

Management

contractor AMEC-Hong Kong Construction Co Ltd Joint Venture

structural engineer Maunsell Consultants Asia

m&e engineer J Roger Preston Ltd

facade technology Meinhardt Facade Technology (HK) Ltd

quantity surveyor Davis Langdon & Seah

|

Hong

Kong is full of glass boxes -- those reflective uniforms in silver,

blue or black that dot the skyline on both sides of the harbour.

Adoption of a modernist idiom, however, need not translate into

anonymity and blandness.

Hong

Kong is full of glass boxes -- those reflective uniforms in silver,

blue or black that dot the skyline on both sides of the harbour.

Adoption of a modernist idiom, however, need not translate into

anonymity and blandness.